Click on the mouse wheel to see the large size ..

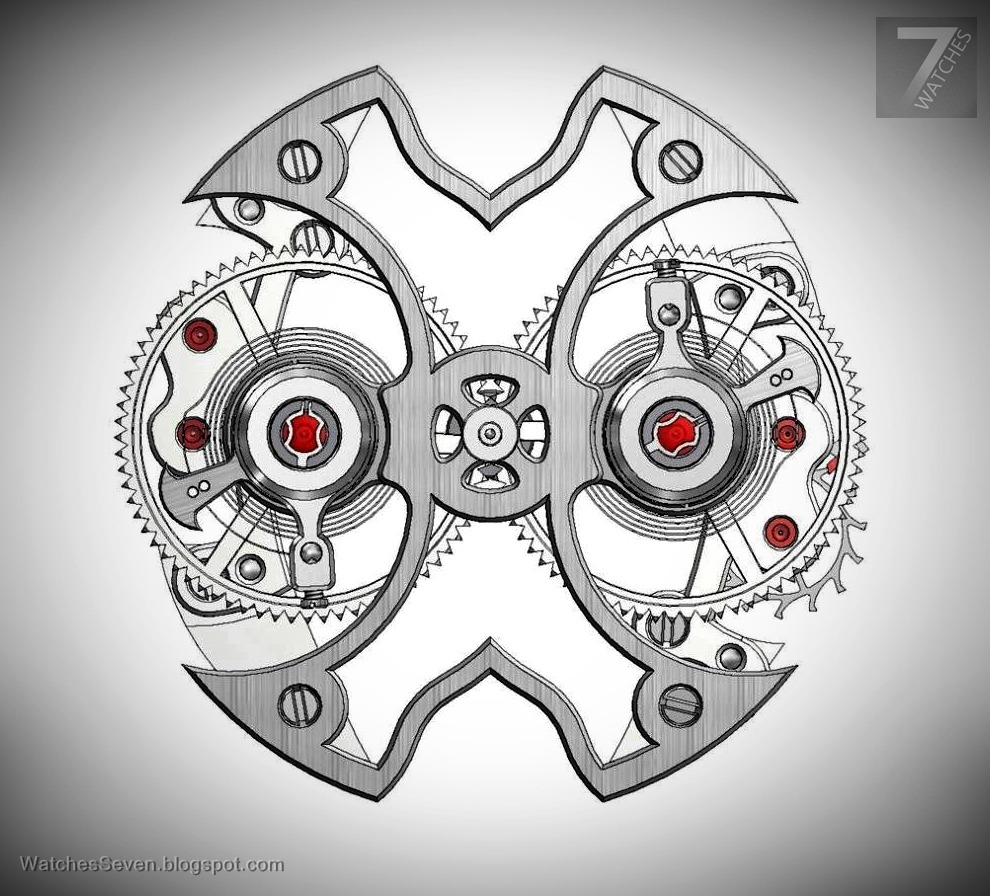

Rudis Sylva is proud to present the RS12 Grand Art Horloger, the third generation of timepieces equipped with the Harmonious Oscillator.

This revolutionary regulator featuring two toothed balances is a unique invention minimising the effects of gravity while showcasing highly sophisticated decorative details hand-worked by the Jura region's finest craftsmen. Its technical characteristics are also exceptional:

The two toothed balances are interlinked. This link ensures the same amplitude. The symmetry and energy of the balance springs are constantly opposed, enabling instantaneous average correction in the vertical position, which minimises the effect of gravity.

The cage turns 360 degrees in 60 seconds

The pallet fork is positioned at 90 degrees

The double barrel ensures a power reserve of 70 hours

The frequency is 21,600 vibrations/hour (3 Hz)

Seconds indicator bridge

Machined from titanium and hand-bevelled, this bridge at 6 o'clock includes no fewer than 28 internal angles. It takes 10 times longer to create a sharp internal angle in titanium than a rounded corner in steel.

Main plate

The lower part of this strategic component features a hand-crafted guilloche decoration of tapering pyramids. From the edge to the centre of the piece, each guilloche line includes 60 pyramids, each one smaller than its neighbour, requiring extremely meticulous guilloche operations.

Engraving

Apparent in the marking on the double barrel bridge or the caseback sundial and inscription, the extremely precise engraving magnifies the skill of the hand-engraver whose painstaking work is carried out under microscope.

Oven-fired enamel

Silica stones are crushed by hand and mixed with water. The resulting material is then applied to the hand-engraved surfaces and placed in a special oven at 840°C. The resulting enamel is then polished to obtain the perfect dial.

The unique technology offered by Rudis Sylva positions the Harmonious Oscillator above most existing tourbillons, since the effects of gravity to which it is subjected are minimised. The hand-finishing makes each piece unique and pays tribute to the various branches of watchmaking artistry.

Click on the mouse wheel to see the large size ...

The Harmonious Oscillator

With its innovative technical features, this design can boast a more accurate setting capacity than a conventional tourbillon, thanks in particular to the asymmetric deployant of the balance springs in all positions, hence the name "Harmonious Oscillator". This world first with two toothed balances exhibits a resonance effect from the first oscillations.

The Harmonious Oscillator is neither a tourbillon nor a carrousel; however they do have some aspects in common:

Each mechanism is mounted on a rotating cage which completes a full revolution in 60 seconds.

The system improves accuracy by counterbalancing disruption of the balance isochronism due to the Earth's gravity.

What are the major differences between the Harmonious Oscillator and a tourbillon or carrousel?

The 3 devices have a complete balance. In the tourbillon, the balance staff is situated on the same line as the tourbillon cage pivots, whereas in the carrousel, the balance staff is eccentric. These two systems take one minute (a full revolution) to compensate for loss of accuracy in the vertical position (effect of gravity).

The Harmonious Oscillator, by means of the interconnection of the balances and asymmetric deployant of the mainsprings, enables instantaneous time correction in the vertical position. In the same position, the tourbillon - provided it is in a totally stable position - needs a minute to correct.

In conclusion, the Harmonious Oscillator offers far better accuracy than most conventional tourbillons or carrousels. This mechanism is close to perfection in terms of time-keeping precision.

Click on the mouse wheel to see the large size ...

Click on the mouse wheel to see the large size ...

Finishing: pays tribute to watchmaking artistry

Bevelling

The bevelling and dashed lines are done entirely by hand. The authenticity of the hand bevelling can be seen in the cleanness of the inward and outward corners, which no machine can reproduce with such precision. This finish consists of eliminating the edges between the surface and flanks of the piece, forming a 45-degree chamfer (bezel) which will then be polished. This operation deburrs "machine-processed" components which, aside from their lack of aesthetic appeal, could adversely affect the operation of the movement. Polishing also limits corrosion. This finishing process requires great meticulousness and offers the finest aesthetics.

The cage bridge of the oscillator, made from titanium, a stronger material than steel, is extremely complicated to make. No fewer than 28 internal angles on this highly visible bridge clearly testify to the perfection of the work undertaken by Rudis Sylva.

Guilloche work

On the dial indicating the hours and minutes, as well as the plate, you can admire the artistry of the hand guilloche work performed by Georges Brodbeck in his Saignelégier workshop. The guilloche craftsman has made a subtle play with a decoration of tapering trapezoids. This decoration is achieved by linear and rotational movement of the piece.

Engraving

In the 19th century, the engravers from our mountains employed their skills in a vast range of fields: medals, stamps, bank notes, prints, image reproduction, jewellery and watchmaking.

Two centuries later, the development of mechanical, chemical or laser engraving industrial techniques has completely altered the engraver's daily work. Only extremely haute horlogerie pieces are now entitled to the craftsman's touch.

Sylvain Bettex and Bertrand Degiorgi have applied their finest work to the hidden face of the timekeeper. Purists will appreciate the chisel work, which cuts to the heart of the flawless lettering with regular bevelling and perfect symmetry, revealing moreover a polished cut completely free from burrs.

This chisel modelling outstrips the "handicraft" of any machine work, and further distinguishes a watch born out of regional talents.

The enamelling

Tucked away in a farm in the peaceful hamlet of Les Barrières, Sophie Cattin Morales practices the art of enamelling in her timeless workshop. As a child she lived on the Les Rosées-Dessous farm that houses the "Ultima Forsan" sundial dating from 1750. So it was an obvious step to call on her talent to enhance the reproduction of the fresco on the back of the Rudis Sylva watch.

Click on the mouse wheel to see the large size .. BIG FOTO

Like a artisan-watchmaker of yesteryear, Sophie, leaning over her window sill, works the enamel bathed in natural light. With her mastery of the traditional technique, she transforms the pieces of raw enamel, grinding them in an agate mortar until the desired grain is obtained. Then she washes them to eliminate any foreign bodies, before finally undertaking the enamelling itself. The enamels are applied using a brush in the champlevés in the gold piece.

Dried out and then fired in a kiln at around 840 degrees, the enamelled half-moon is honed to obtain a flat surface, and then placed back in the kiln to undergo a final operation, known as glazing. After the enamel surface has been vitrified to give it a shine, it undergoes a final polish. Making colours eternal, unalterable by light - such is the power and privilege of the art of enamelling.

---------------------------------------

Technical Specifications

RS12 Grand Art Horloger

Case 18kt rose or white gold

Width 44mm

Height 14.3mm

Case finish vertical satin finish

Bezel finish polished

Horn finish welded, polished and micro-blasted

Inter-horn 23 mm

Back rose gold or white gold, screwed

Engraving by hand

Decoration hand-engraved sundial with overn-fired enamel

Sundial origin artisan watchmaker's farmhouse from 1750, Les Bois

Strap real alligator, large scales with tassel

Buckle tongue 18kt rose gold or white gold

Crown 18kt rose gold or white gold with engraved logo

Brand logo 3 fir trees on 3 mountains

Logo symbol Settling of the Jura Valley around 1350A.D.

Dial hour, minute and second indicator

Hour and minute indicator ring sundial decoration

Second indicator ring bevelled

Hand centre hand guilloche work

Hand guilloche work pattern progressive circular pyramids

Hands gold, hand decorated

Decoration drawing on the 2 faces, bevelling on the flanks

Main plate hand guilloche worked, 60 tapering pyramids

Movement Harmonious Oscillator

Dimensions h. 7.78 mm / 39.55 mm

Winding manual, 49 crown revolutions

Power reserve about 70 hours

Manufacture made by Rudis Sylva

Purchases from third parties escapement, jewels, spring, Incabloc

Indicators hour, minute, seconds

Main plate machining on machine with bed plate, 175 operations

Precision-tested 100% of components

Balances toothed, interlinked, ensuring the same amplitude

Escapement only 1 with 1 pallet fork positioned at 90 degrees

Frequency 21,600 vibrations/hour (3 Hz)

Cage rotation 360 degrees in 60 seconds

Cage diameter 17.40 mm

Balance-springs 2, flat, asymmetric deployant

Balance-spring symmetry and energy constantly opposed

Vertical gravity correction instantaneous, minimising the effect of gravity

Finishing Haute Horlogerie finishing

Main plate bevelling, tapering pyramid guilloche work

Bridges hand-decorated, bevelling, circular graining, drawing

Gear train circular graining, diamond-polished corners

Screws machine threading with controlled undercut

Barrel drum snailed

Titanium cage bridge bevelling, 28 internal angles, drawing (30 hours' work)

MSRP is 250,000 Swiss Francs.

--------------------------------------------------------

www.facebook.com - Rudis.Sylva

-------------------------------------------------------------

www.RudisSylva.ch

No comments:

Post a Comment