GIRARD-PERREGAUX – Tri-Axial Tourbillon Limited Edition NEW

The Tri-Axial Tourbillon represents a major success for Girard-Perregaux, a historic specialist in the mastery of this precision watch mechanism. This is a new step for the Manufacture in its quest for chronometric perfection with a high-speed tourbillon on three separate axes.

Click on the mouse wheel to see the large size ... BIG FOTO

A complex mechanism aimed at optimizing chronometric precision, the tourbillon has been a specialty of Girard-Perregaux for over a century and a half. Once again, the Manufacture at La Chaux-de-Fonds demonstrates its mastery of the subject, taking its search for precision even further with the Tri-Axial Tourbillon.

Click on the mouse wheel to see the large size ... BIG FOTO

This development embodies the quintessence of time measurement based on the physical principle of the elimination of disturbances, the first being the Earth's gravitational pull. As it is designed on three planes instead of the traditional one, the Tri-Axial Tourbillon optimizes its performance and showcases a captivating spectacle.

Click on the mouse wheel to see the large size ... BIG FOTO

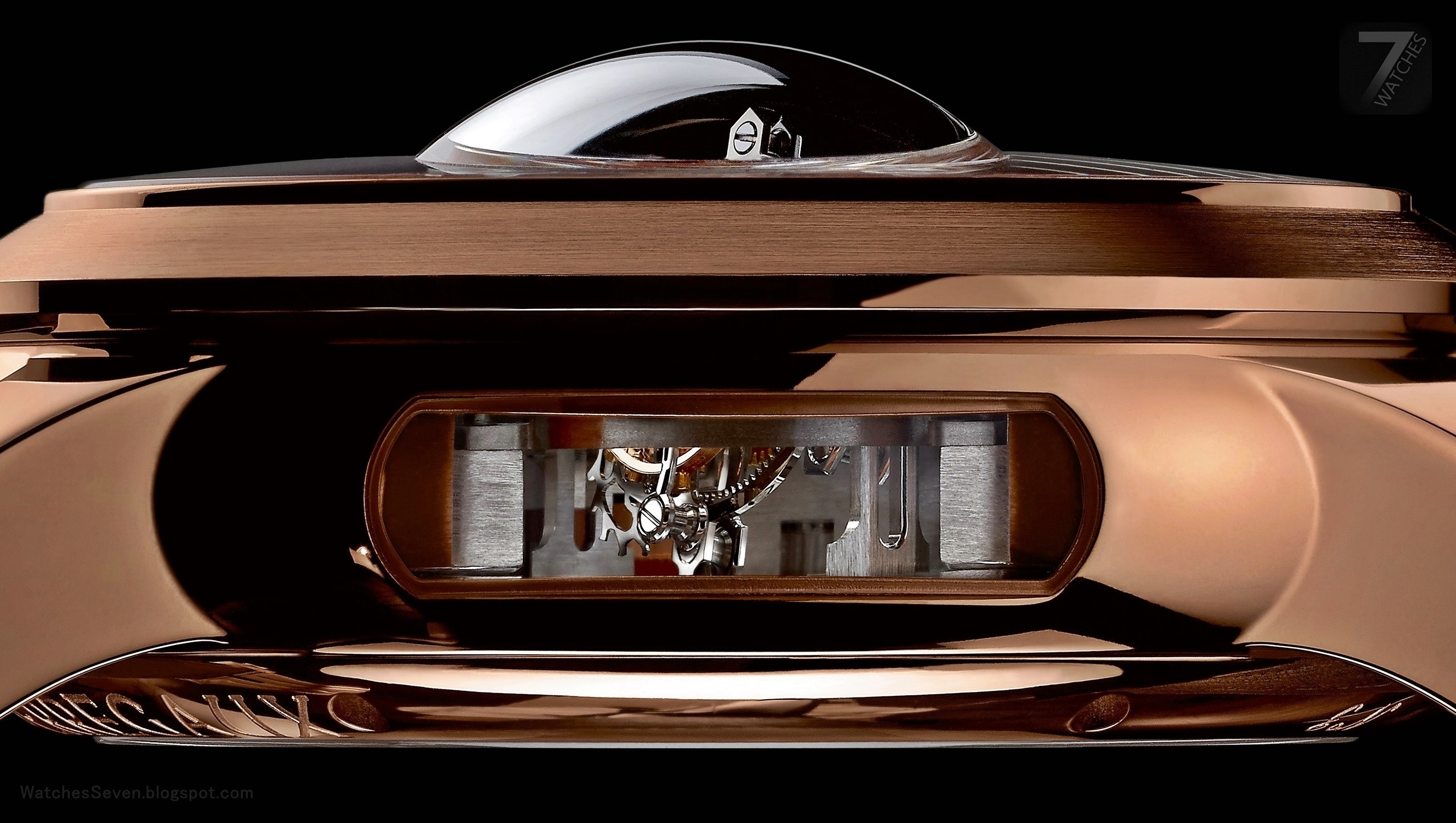

The external parts therefore needed to be specially adapted in order to integrate this extraordinary caliber. The tourbillon's triple cage required the integration of a domed lens that rests against the sapphire crystal in order to provide the necessary interior volume.

Click on the mouse wheel to see the large size ... BIG FOTO

With the Tri-Axial Tourbillon, Girard-Perregaux therefore delivers a brilliant demonstration of its expertise and its constant search for watchmaking excellence.

Click on the mouse wheel to see the large size ... BIG FOTO

Three axes

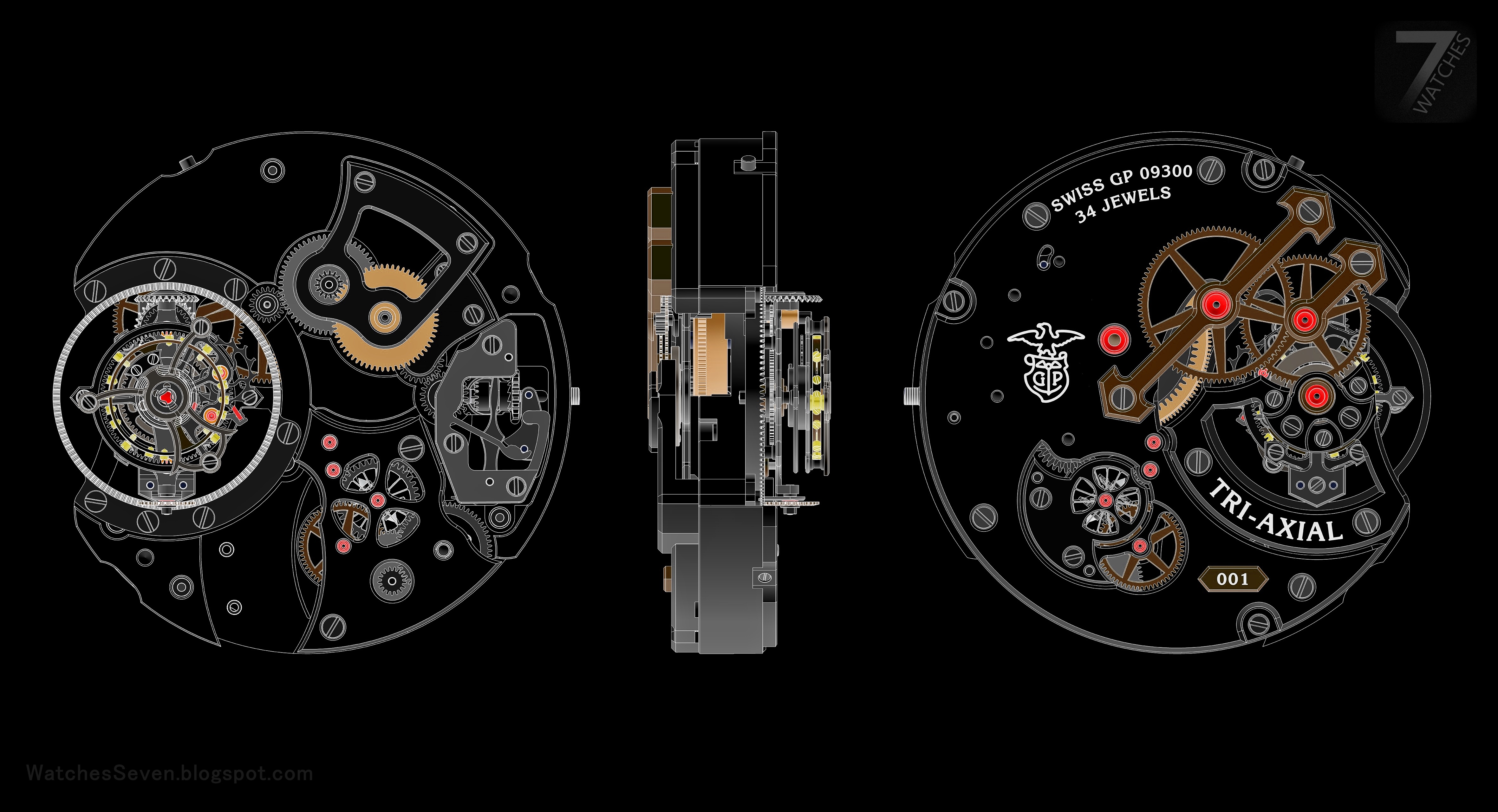

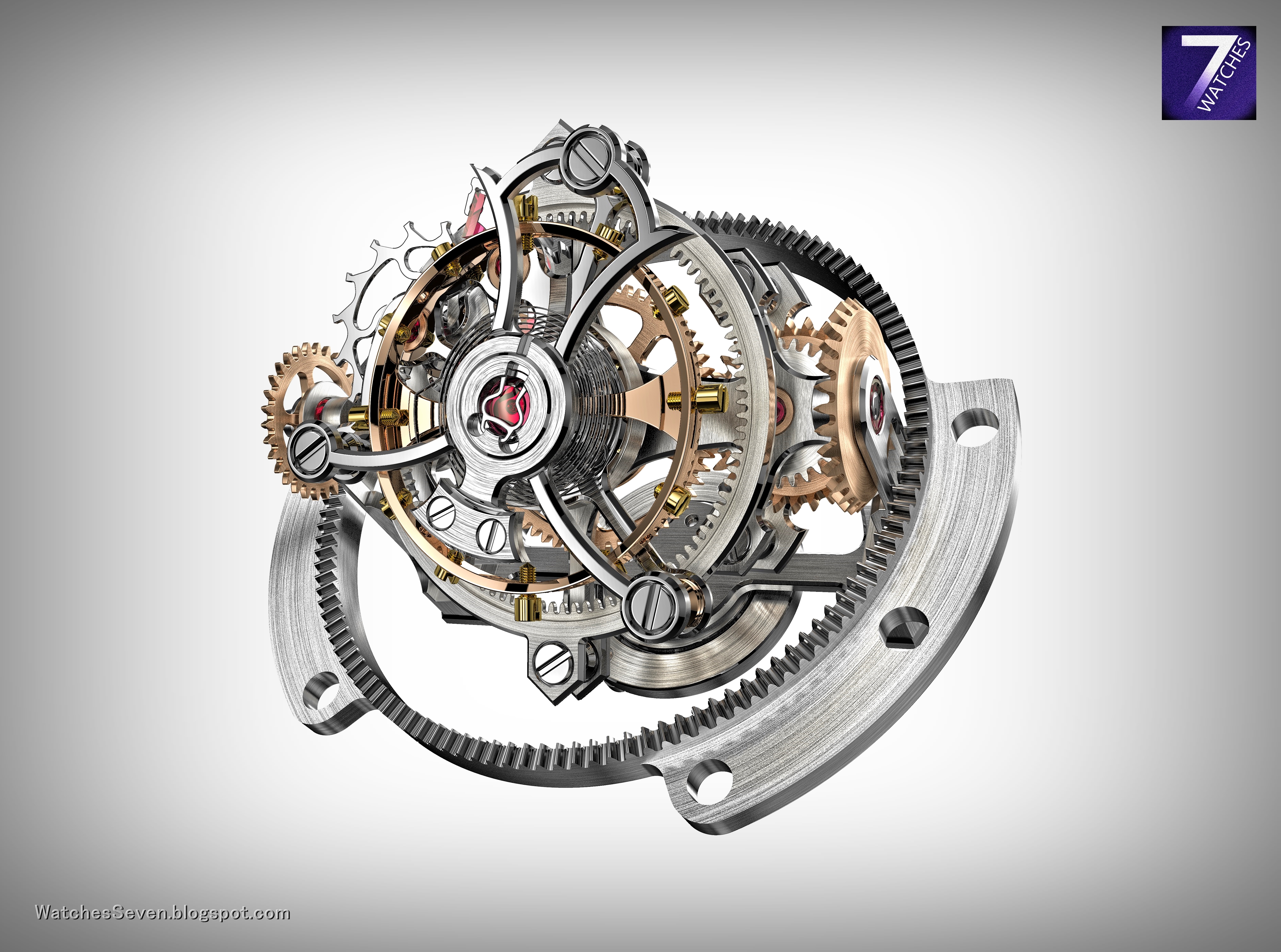

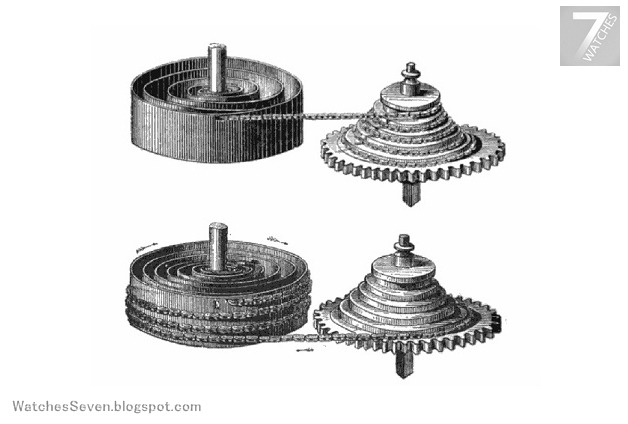

The Tri-Axial Tourbillon by Girard-Perregaux features a regulator on three separate axes. At its heart beats a traditional tourbillon. Its cage performs one rotation in one minute.

Click on the mouse wheel to see the large size ... BIG FOTO

It is integrated within a structure positioned on a second axis and performs a complete rotation in 30 seconds. Finally, both are inserted into a third system. The ensemble is placed on a third axis and performs one rotation in 2 minutes. The diameter of the ensemble comes to 13.78 mm.

Click on the mouse wheel to see the large size ... BIG FOTO

With a total weight of 1.24 grams, the cage and the drive systems are made of steel. The support pillars are in titanium, or in pink gold to act as a counterweight where the kinetic balance required this. As for the balance, it integrates 16 pink gold adjustment micro-screws. It has an increased frequency of 3 Hz, or 21,600 vibrations per hour.

Click on the mouse wheel to see the large size ... BIG FOTO

Exceptional finishes

A masterpiece of modern engineering, the Tri-Axial Tourbillon caliber remains absolutely faithful to the purest of traditions. The cage adopts the lyre shape that has been characteristic of Girard-Perregaux Tourbillons since the 19th century. Haute Horlogerie timepieces demand components that are decorated and finished by hand with the greatest care. They therefore present mirror-polished surfaces and perfect chamfering (especially on a number of inward angles which are particularly difficult to finish).

Click on the mouse wheel to see the large size ... BIG FOTO

The gear train is circular-grained and the sides are satin-brushed. On the case-back, the eagle, the symbol of the manufacture since 1897, is engraved and a plaque in the arrow shape of the Tourbillon with Three Bridges' iconic bridges bears the individual number of each piece. This shape is also found on the emblematic gold bridges also visible on the back of the movement.

Click on the mouse wheel to see the large size ... BIG FOTO

laying hours, minutes and a time reserve indicator, the new GP09300 mechanical caliber with manual winding measures 36.10 mm in diameter with a height of 16.83 mm. It comprises 317 components and has a minimum power reserve of 52 hours.

Click on the mouse wheel to see the large size ... BIG FOTO

Multiple dial

Constructed on several levels, the dial of the Tri-Axial Tourbillon presents a wide aperture at 9 o'clock that reveals the hypnotic ballet of the regulation system.

Click on the mouse wheel to see the large size ... BIG FOTO

At half past one, a silver dial with Clous de Paris motif presents numerals and hour markers in pink gold. It is encircled with an applique in pink gold and a black flange that displays the minutes numerals in white. The beveled, skeleton-shaped dauphine hands are crafted from pink gold.

Click on the mouse wheel to see the large size ... BIG FOTO

Starting at the center of the watch, the power reserve indicator follows a curve that ends at 6 o'clock. Designed graphically to form an array of circles and curves, the dial presents concentric, regular stripes in the areas that have been left empty. Like Japanese zen stone gardens, these gray-colored areas counterbalance the clear technicality of the timepiece with their understatement and simplicity. Girard-Perregaux's initials gleam in pink gold at 11 o'clock.

Click on the mouse wheel to see the large size ... BIG FOTO

Complex sapphire crystal

Crafted from pink gold, the case respects the design codes of Girard-Perregaux's Haute Horlogerie collection with a beveled bezel, a rounded case-center and lugs that narrow out elegantly towards the exterior. The superior sapphire crystal presents a spectacular construction. At 9 o'clock, a domed sapphire crystal, designed to highlight the tourbillon's three axes, is applied to the main crystal, which is first pierced to the required diameter.

Click on the mouse wheel to see the large size ... BIG FOTO

A toric-shaped sapphire crystal is also integrated into the side of the case at 9 o'clock in order to show this fascinating spectacle from another angle. Finally, the case-back, which is screwed and transparent, reveals the entire movement and, in particular, the satiny circular bridge engraved with the words "Tri-Axial" that supports the differential of the tourbillon system.

Click on the mouse wheel to see the large size ... BIG FOTO

The Tri-Axial Tourbillon is available in a 10-piece limited edition.

-------------------------------------------------

TECHNICAL SPECIFICATIONS

Reference: 99815-52-251-BA6A

Case: pink gold

Diameter: 48.00 mm

Dial: gray anthracite

Crystal: anti-reflective sapphire with dome to cover the tourbillon

Case-back: anti-reflective domed sapphire crystal

Apertures on the side to reveal the movement / anti-reflective toric crystal

Water resistance: 30 meters (3 ATM)

Movement

Girard-Perregaux movement GP09300-0001

Mechanical, manual winding movement

Diameter: 36.10 mm (16 ''')

Thickness: 16.83 mm

Frequency: 21,600 Vib/h - (3 Hz)

Power reserve: min. 52 hours

Jewels: 34

Number of components: whole movement: 317

Two-arrow Bridges: in pink gold

Tourbillon:

- Tourbillon cage: 140 components for 1.24 g

- 3 axes

- One rotation every 1 minute on the first axis, every 30 seconds on the second axis, every 2 minutes on the third axis.

- Poised upper and lower cages with pink gold counterpoise

- Beveled and hand-polished pallets bridge

- Balance wheel: variable inertia with pink gold setting screw

All components of the movement have hand finishing according to Haute Horlogerie criteria.

Functions: Tri-Axial tourbillon, hour, minute, power reserve indicator

Wristband

Black alligator leather strap with hand stitches

Pink gold folding buckle

Limited edition: 10-piece

Functions: Tri-Axial tourbillon, hour, minute, power reserve indicator

Wristband

Black alligator leather strap with hand stitches

Pink gold folding buckle

Limited edition: 10-piece

--------------------------------------------

www.facebook.com - Girard Perregaux

----------------------------------------------------------------

www.Girard-Perregaux.com