Sinn Spezialuhren – 1800 S DAMASZENER Limited Edition NEW

Where functionality defines design and every little detail serves to highlight the innovative technology at play, this is where Sinn Spezialuhren is at work. Since our establishment in 1961, we focused continuously on high-quality mechanical watches combining a traditional sense of quality with advanced solutions.

Click on the mouse wheel to see the large size ... BIG FOTO

This has repeatedly resulted in the use of totally new watchmaking materials. In 1995, we presented the first watch made of 22-carat yellow gold with a material hardness equal to that of stainless steel (220 HV). In 2005, German Submarine Steel was used for the first time in diving watches.

Click on the mouse wheel to see the large size ... BIG FOTO

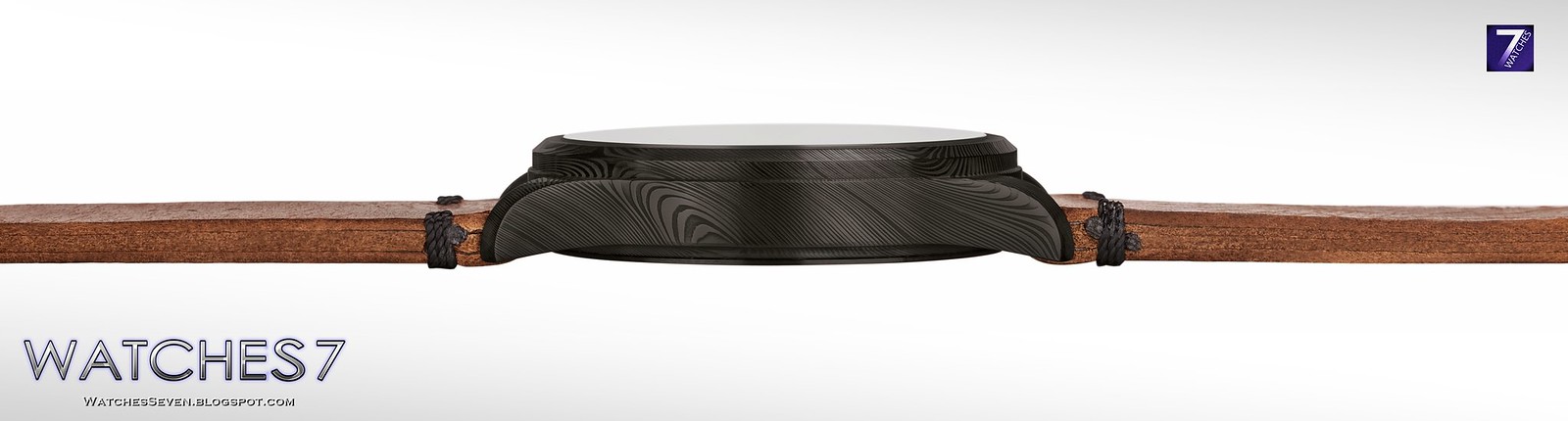

Our 1800 S model made of Damascus steel (ger.: Damaszener Stahl) seamlessly follows on from this by rendering the highly traditional material appropriate for watch cases – without forsaking but rather enhancing its special allure.

Click on the mouse wheel to see the large size ... BIG FOTO

The watch thus displays a uniqueness that is immediately reflected in its design and appearance. In order to bring the characteristics textures of Damascus steel to the fore – an organic pattern of alternating bands of light and dark – the dial and central part of the case are forged from a complete steel block rather than designed as separate components, as is customary.

Click on the mouse wheel to see the large size ... BIG FOTO

The result is rather remarkable: for the Damascus pattern on the dial continues across the entire case to create a fascinating and impressive whole. Thanks to the use of TEGIMENT Technology and the application of an additional Black Hard Coating, we have succeeded in combining functionality with high quality. The Black Hard Coating displays the pattern in a subtle, exquisite light and ensures good readability and a masculine-looking watch.

Click on the mouse wheel to see the large size ... BIG FOTO

Damascus steel has fascinated humankind for centuries. It gained its legendary reputation above all in the making of swords, knives and blades. Damascus steel is a combination of at least two different types of steel, layered to create the aforesaid surface design. The traditional art of making Damascus steel is very elaborate and portrays a unique blend of craftsmanship and application. During production, the different types of steel are layered and forge-welded together.

Click on the mouse wheel to see the large size ... BIG FOTO

Click on the mouse wheel to see the large size ... BIG FOTO

The piece is then forged, halved while in a glowing state and layered together again. Experts refer to this as ‘folding’. By combining soft and hard steels, a new kind of steel is created, one which displays properties of both. In the final stage of production, the Damascus pattern is made visible through surface etching. The steels are dissolved to varying extents by acid, thus forming the typical light and dark nuances.

Click on the mouse wheel to see the large size ... BIG FOTO

Click on the mouse wheel to see the large size ... BIG FOTO

Limited to 100 pieces

Case with integrated dial in Damascus steel

Case made with Black Hard Coating on a TEGIMENT Technology basis

Damascus steel case back

Case back made with Black Hard Coating on a TEGIMENT Technology basis

Sapphire crystal glass

Crown screwable

Meticulously appliqués

Pressure-resistant up to 10 bar

Low pressure resistant

Click on the mouse wheel to see the large size ... BIG FOTO

In this respect, it is important to know that the use of Damascus steel in the making of watch cases is particularly challenging with regard to corrosion resistance. In order to find a professional solution, we adapt recent developments in materials engineering. For the case of our 1800 S DAMASZENER model, the different steels used are combined using powder metallurgy and, in this sense, technically optimised.

Click on the mouse wheel to see the large size ... BIG FOTO

Also during production of the 1800 S DAMASZENER, the layered structure is made visible through final surface etching, which gives the material its characteristic appearance. Each watch thus becomes an extraordinary and unique timepiece, as the flow of lines cannot be physically manipulated.

Click on the mouse wheel to see the large size ... BIG FOTO

-------------------------------------------------------

Technical details

Movement

Mechanical Movement

ETA 2892-A2

Self-winding mechanism

21 bearing jewels

28,800 semi-oscillations per hour

Seconds stop function

Shock resistant as per DIN 8308

Anti-magnetic as per DIN 8309

Case

Case with integrated dial in Damascus steel

Damascus steel case back

Sapphire crystal glass, anti-reflective on both sides

Case back screw-fastened

Crown screwable

Meet the technical requirements for waterproofness, as set out in standard DIN 8310

Pressure-resistant up to 10 bar

Low pressure resistant

Functions

Hours, minutes, seconds

Date display

SINN Technologies

Black Hard Coating on a TEGIMENT Technology basis

Dimensions and Weight

Case diameter: 43 mm

Band lug width: 22 mm

Dial and Hands

Dial in Damascus steel

Indices made of 13 meticulously appliqués

Indices coated with luminescent colour

Hour and minute hand coated with luminescent colour

Warranty

2 years

Limited edition to 100 units

----------------------------------------------

SINN SPEZIALUHREN GMBH

Im Füldchen 5–7 • 60489 Frankfurt am Main

• Tel. +49 (0)69 / 97 84 14-0

• Fax +49 (0)69 / 97 84 14-201

• info@sinn.de

--------------------------------

www.facebook.com - Sinn Uhren

-------------------------------------------------

www.Sinn.de